Green Valve High Quality brass fitting 1/8 12mm pneumatic quick connectors

Green Valve High Quality brass fitting 1/8 12mm pneumatic quick connectors

Klikkon has its own R&D department that, in close cooperation with the client, customizes new products from idea to end product and, following a sampling phase, prepares them for production.

From the Klikkon factory You can expect products of top quality.

Our service, technical advise and logistic handling are an important part of our quality. We guarantee quality with the next basic principles in mind:

· Continuous attention to prevent defaults (zero defaults)

· Maximum on time delivery

· Continuous improvement process.

All Business Units of the Klikkon group work according international quality standards certified according ISO 9001:2008.

Material used for Brass Fittings

Straight bodies: Barstock CA 360 or CA 345

Shape bodies: Extruded barstock CA 360 or Forged CA 377

Nuts: Barstock CA 360 or Forged CA 377

Green Valve High Quality brass fitting 1/8 12mm pneumatic quick connectors

Green Valve High Quality brass fitting 1/8 12mm pneumatic quick connectors

|

Material Standard |

Cu铜 |

Pb铅 |

|

HPb59-T(企) |

57~59 |

≤2.8 |

|

HPb59-SG |

57~59 |

≤2.8 |

|

GB-HPb59-1抛光 |

57-60 |

0.8~1.9 |

|

HPb59-SG2 |

≥57 |

0.8~1.9 |

|

挤压HPb59-T(企) |

57~59 |

≤3.0 |

|

抛光HPb59-T(企) |

58~60.5 |

0.8~1.9 |

|

无铝抛光HPb59-T(企) |

58~60 |

≤2.3 |

|

抛光挤压HPb59-T |

57~59 |

≤2.8 |

|

普抛HPb59-T(企) |

57~59 |

≤2.8 |

|

HPb59-T(A) |

57~59 |

≤3.0 |

|

HPb58-3 |

57~59 |

2.5~3.5 |

|

H62 |

60.5~63.5 |

≤0.08 |

|

HPb62-0.8(国) |

60~63 |

0.5~1.2 |

|

Klikkon brass certification |

|||||||||||

|

Pos. |

Size |

Quality |

TONS |

|

|||||||

|

1 |

10 |

Hpb58 |

1.3 |

||||||||

|

2 |

15 |

Hpb58 |

0.9 |

||||||||

|

3 |

25 |

Hpb58 |

2.2 |

||||||||

|

4 |

30 |

Hpb58 |

2.8 |

||||||||

|

|

|

|

|

||||||||

|

Chemical analysis |

|

|

|

|

|

|

|

|

|

|

|

|

Pos. |

Cu |

Sn |

Pb |

Zn |

Fe |

Ni |

Si |

Mn |

Al |

ag |

% |

|

1 |

57.32 |

0.8 |

0.75 |

rest |

0.375 |

0.262 |

0.02 |

0.02 |

|

|

% |

|

2 |

58.22 |

0.96 |

0.9 |

rest |

0.387 |

0.267 |

0.01 |

0.02 |

|

|

% |

|

3 |

57.03 |

1.11 |

1.1 |

rest |

0.378 |

0.27 |

0.01 |

0.02 |

|

|

% |

|

4 |

58.18 |

0.97 |

1.2 |

rest |

0.411 |

0.26 |

0.01 |

0.02 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mechanical values |

|||||||||||

|

Pos. |

Yield stress: N/㎡ |

Tensile strength:N/㎡ |

Elongation:% |

Reduction of area: % |

Impact V:J |

Hardness: |

|||||

|

1 |

135 |

360 |

29.5 |

|

|

|

|

|

|||

|

2 |

128 |

370 |

30 |

|

|

|

|

|

|||

|

3 |

135 |

365 |

29.8 |

|

|

|

|

|

|||

|

4 |

140 |

375 |

32 |

|

|

|

|

|

|||

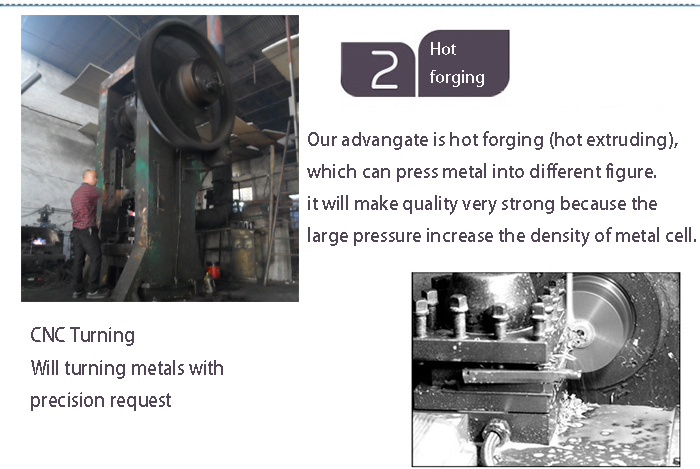

Extruded Barstock Fittings Hexagon, round and shaped bars are extruded in the configuration required, drawn to size, cut to length and straightened. First a solid round billet (8 to 12 inches in diameter) is heated to the pliable state and forced by pressure of approximately 80,000 pounds per square inch through a die. The resulting continuous length of bar is cooled and then drawn through dies to the desired external size. ( The drawing process also controls the temper). After straightening, the bar is ready for machining. The process produces a dense, nonporous material somewhat stronger in the longitudinal direction due to an orientated flow of the grain.

Forged Fittings Material for forging is extruded in round bars, cut to length and straightened. (At this point in the process, forging rod differs from round extruded machinable bars only in temper and chemical properties). After straightening, the bars are cut again into slugs (short lengths), reheated to the pliable state and pressed under a pressure of approximately 25,000 pounds per square inch between upper and lower die cavities. After cooling, the flash is trimmed away and the forging blank is ready for machining. This process of forming under extreme pressure produces a uniformly dense material of exceptional strength. Because grain flow follows the contour, the fitting has high impact strength and is resistant to mechanical shock and vibration.

Why Brass Fittings? Brass fittings are popular because they are strong and durable and hence widely used in industrial and residential applications. The use of brass to make various fittings provides a distinct look because of its yellow color. The advantages of brass for fittings include its good corrosive resistance, and also its plating, joining, polishing and finishing characteristics. Brass as a material is easily machined and hence can be given any shapes of the various types of fittings available.